From software to hardware, we offer integration services of our robotic systems with third-party products.

Thanks to our flexible platform and low overhead, we can fully customize our instruments for specific applications at low cost.

From software to hardware, we offer integration services of our robotic systems with third-party products.

Thanks to our flexible platform and low overhead, we can fully customize our instruments for specific applications at low cost.

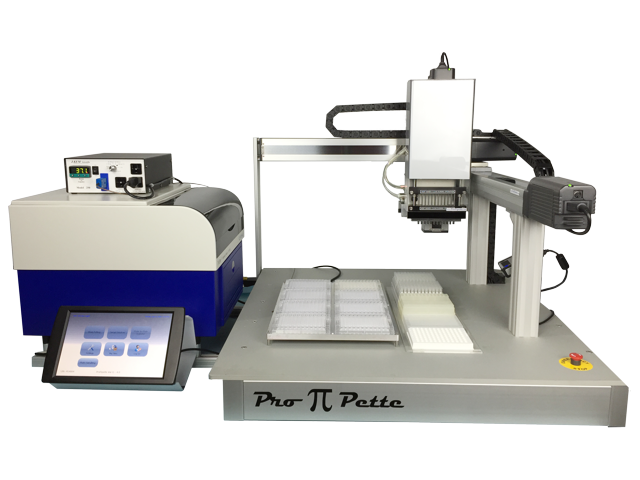

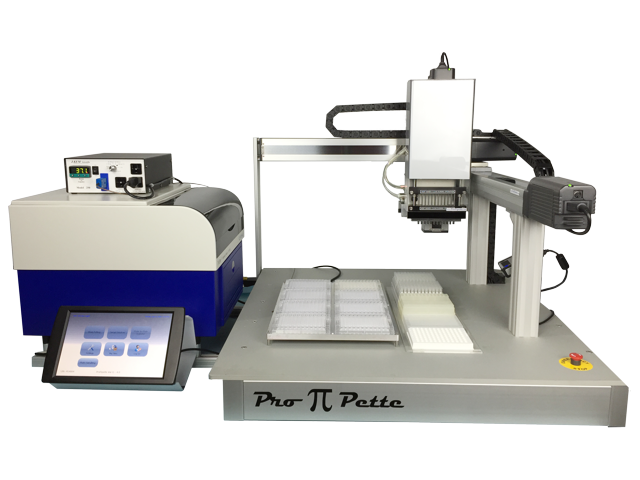

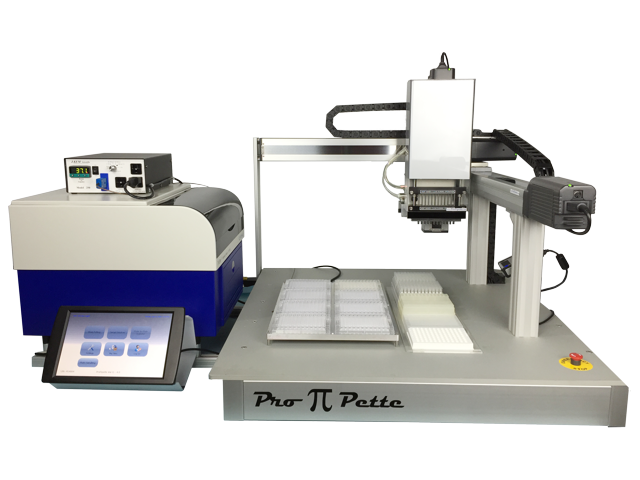

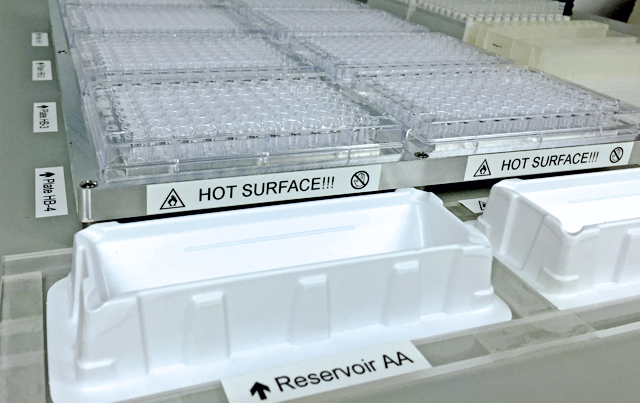

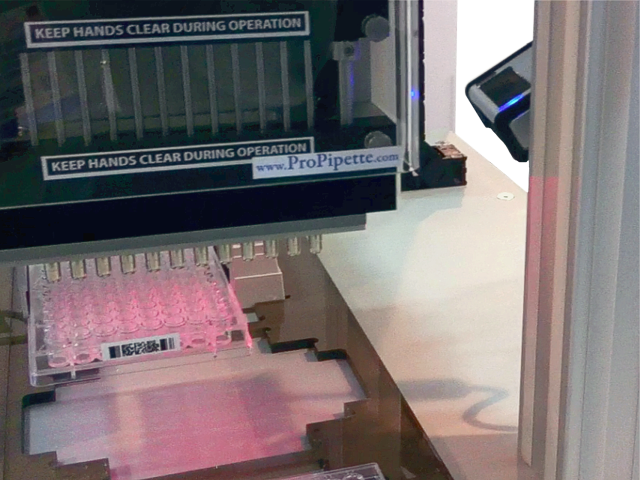

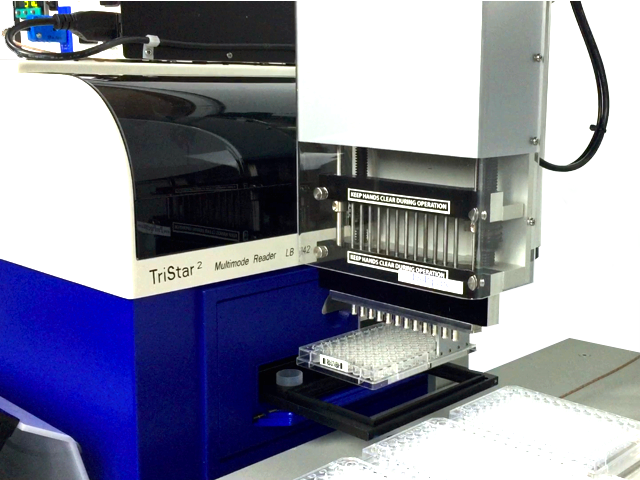

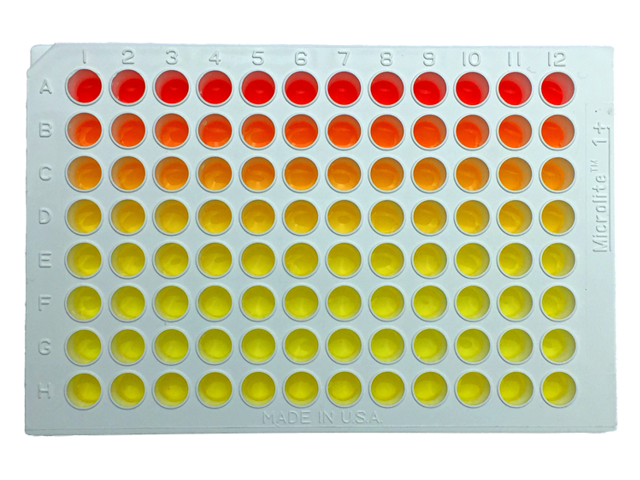

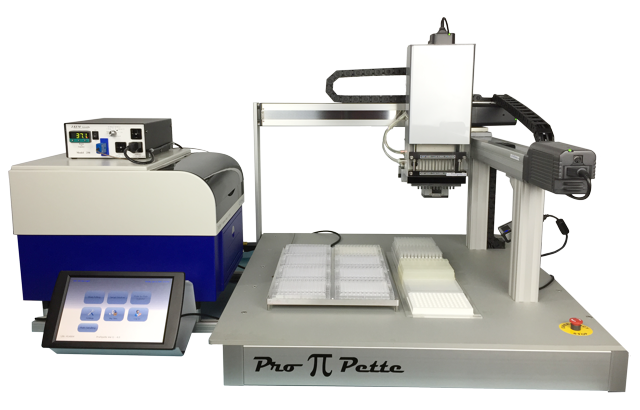

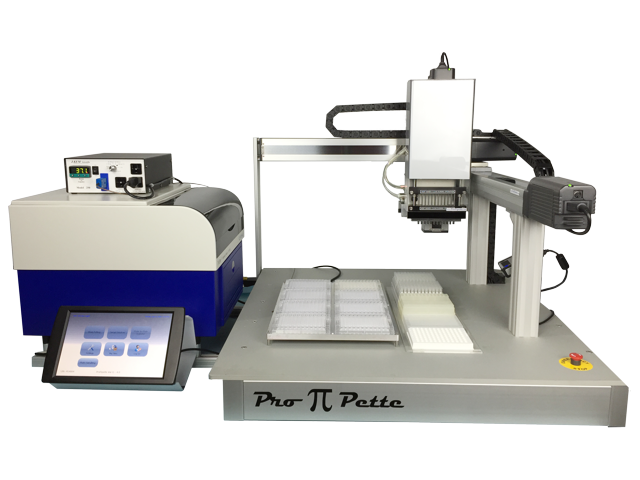

The pictures below show our ProPipette robotic system working with a microplate reader for absorbance, fluorescence, and luminescence. The ProPipette does all plate preparation and incubation with a custom made heated plate. All plate manipulation is done with a built-in gripper. All the information retrieved from the plate reader, barcode reader and protocol logs is compiled and maintained for further processing and analysis.

Thanks to our user friendly software our customers are able to program and develop their own protocols in a few hours!

Fully Customized ProPipette Robotic Station

Custom made heated block for microplate incubation

2D Barcode Reader integration

Gripper for plate handling

From software to hardware, we offer integration services of our robotic systems with third-party products.

Thanks to our flexible platform and low overhead, we can fully customize our instruments for specific applications at low cost.

We offer both software and hardware engineering for a variety of projects. From a simple printed circuit board to a complex robotic system, we can take a concept and turn it into a working prototype.

Here are some of our areas of expertise:

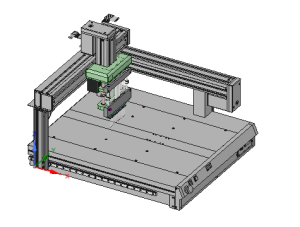

– Prototype and conceptual modeling with Computer-aided drafting software (CAD)

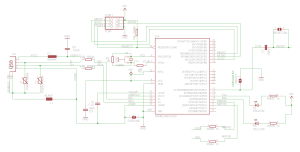

– Printed circuit board design (digital, analog and mixed-signals)

– Instrumentation and signal conditioning

– Embedded systems design and firmware programming

– PC or embedded programming in different languages (Windows CE, Windows .NET, C, C++, Visual Basic among others)

– Touch screens (integration of commercial HMI or design your own touch screen controller in volume applications)

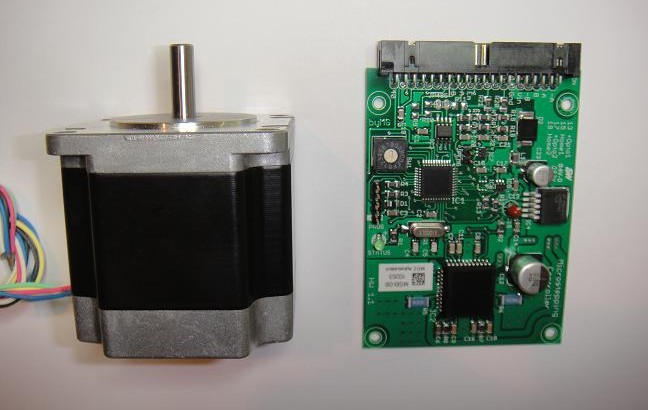

– Servo motors (AC, BLDC, DC, Stepper) for automated systems and positioning

– Integration services with other automated systems or products

– Machine Vision and Machine Inspection (stand alone cameras or PC implementation)

– 2D codes and barcode generation and decoders (PC based or stand alone modules)

– Automation with small-articulated robotic arms or SCARA robots

– Data acquisition systems

– Prototyping and turnkey services.

– Consulting services.

– Integration and Programming of Commercial HMI and Windows CE touch screens with PLCs or embedded systems.

– Custom Design of touch screen controllers for OEM applications.

– Multiple digital I/O , analog I/O channels and communication ports (USB, RS232, RS485 and CAN)

– Large selection of touch screens from 3.5” to 17”.Choose from widescreen, high speed, high resolution, full size or compact models to meet your automation and control needs.

– Complete Robotic System Solution when integrated with the interconnection board and stepper or servomotor controllers.

– Fully Configurable Current, Voltage, Velocity and Position Limits.

– PID + FF Position and Velocity

– Space Vector Modulation .

– ASCII protocol over RS485 and RS232

– Open loop or close loop operation with incremental encoder.

– Multiple digital I/O and analog I/O channels.

– Multi-axis interpolation operation.

– Multiple axis coordinated motion.

– Completely software configurable.

– Full, half and micro-stepping modes.

– Simple ASCII communication protocol over RS485.

– Open loop or close loop operation with incremental encoder.

– Multiple digital I/O and analog I/O channels.

– Parallel, synchronic and linear interpolation operation.

– Multiple axis coordinated motion.

– Completely software configurable.

– Customizable firmware and communication protocol (special order)